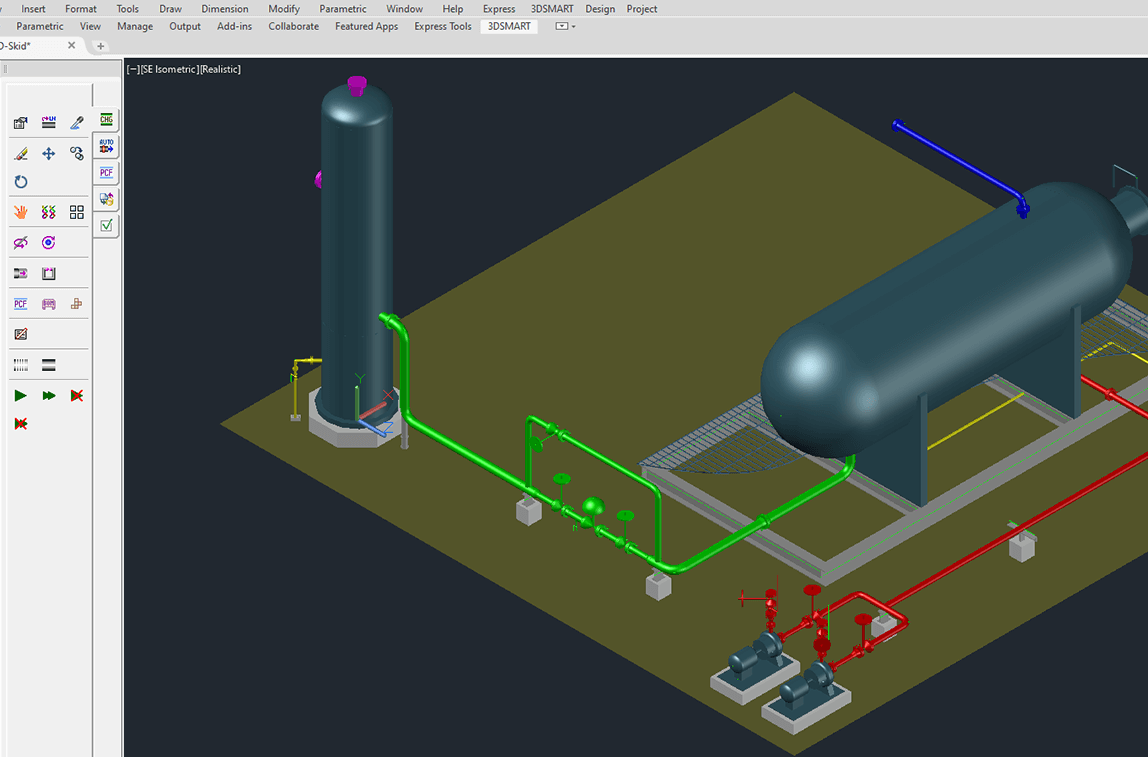

With increasing emphasis on safety in oil and gas installation, it is critical to ensure manufactured components are soundly constructed.

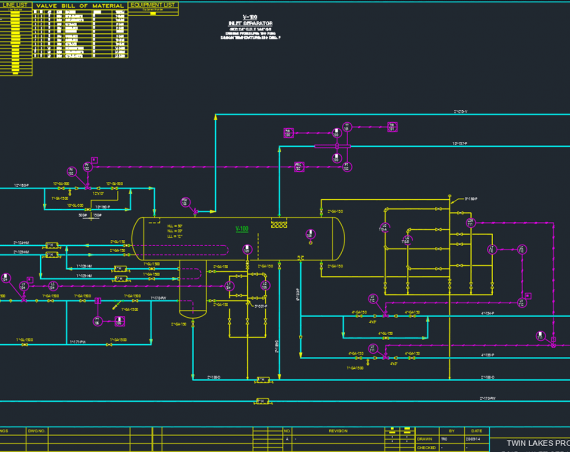

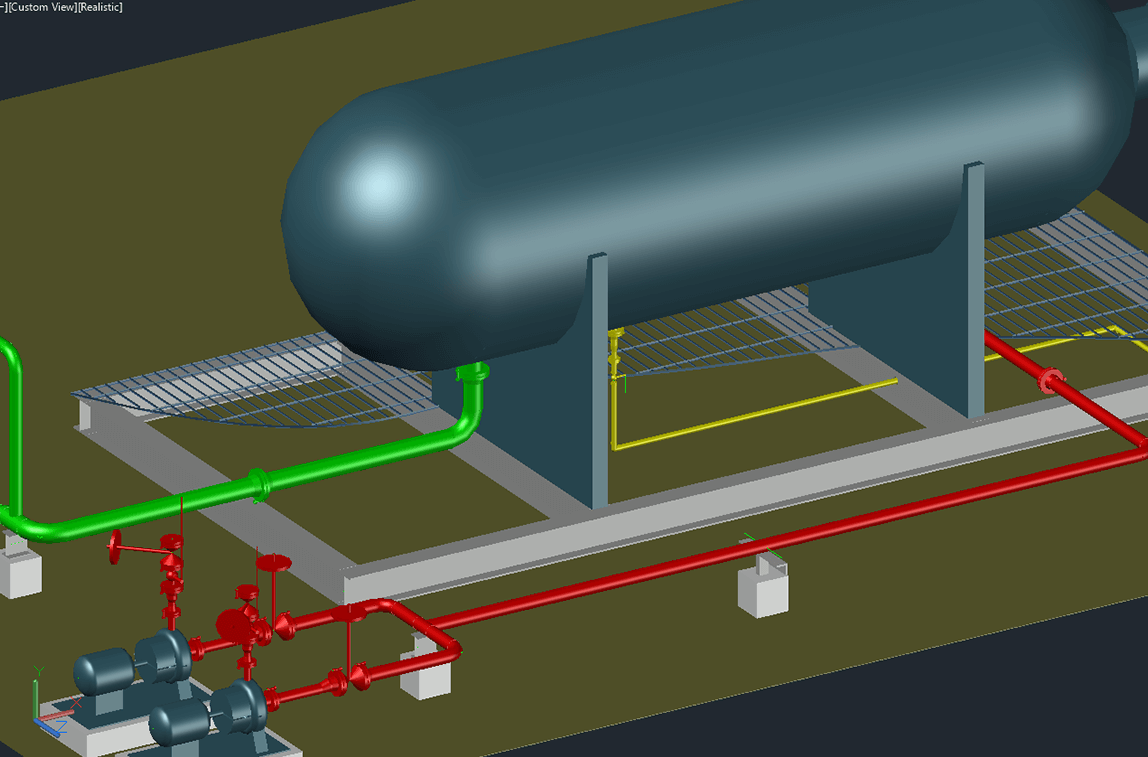

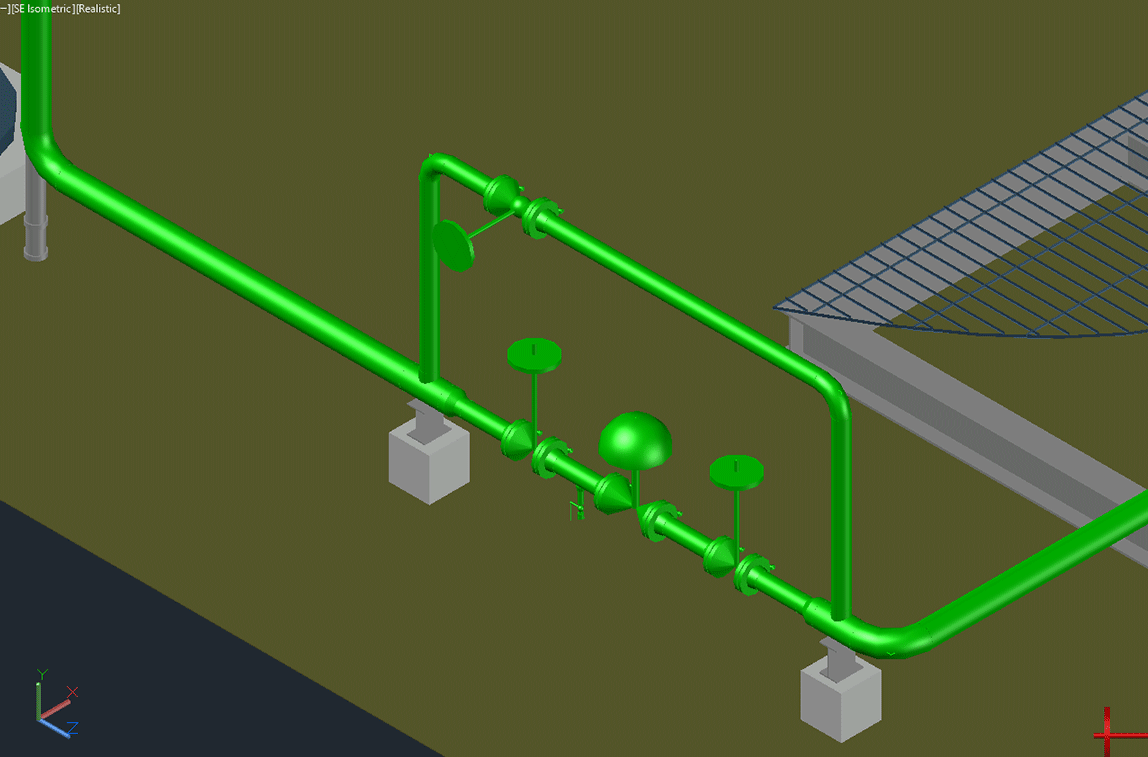

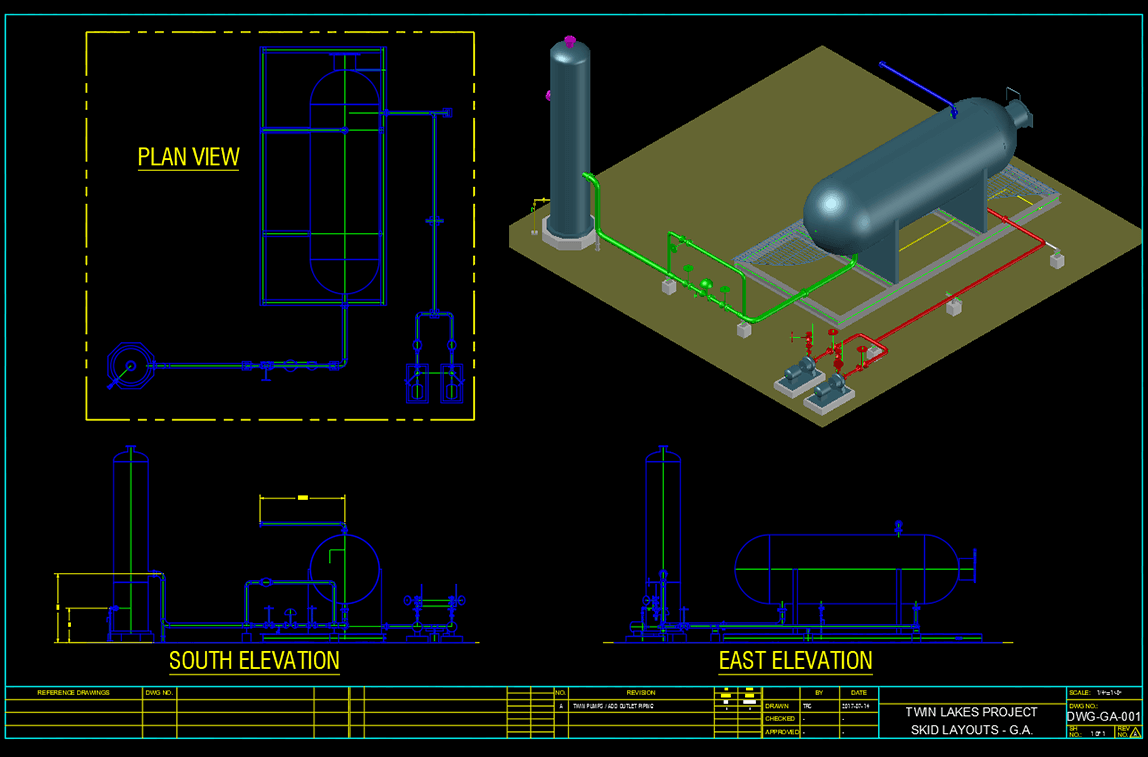

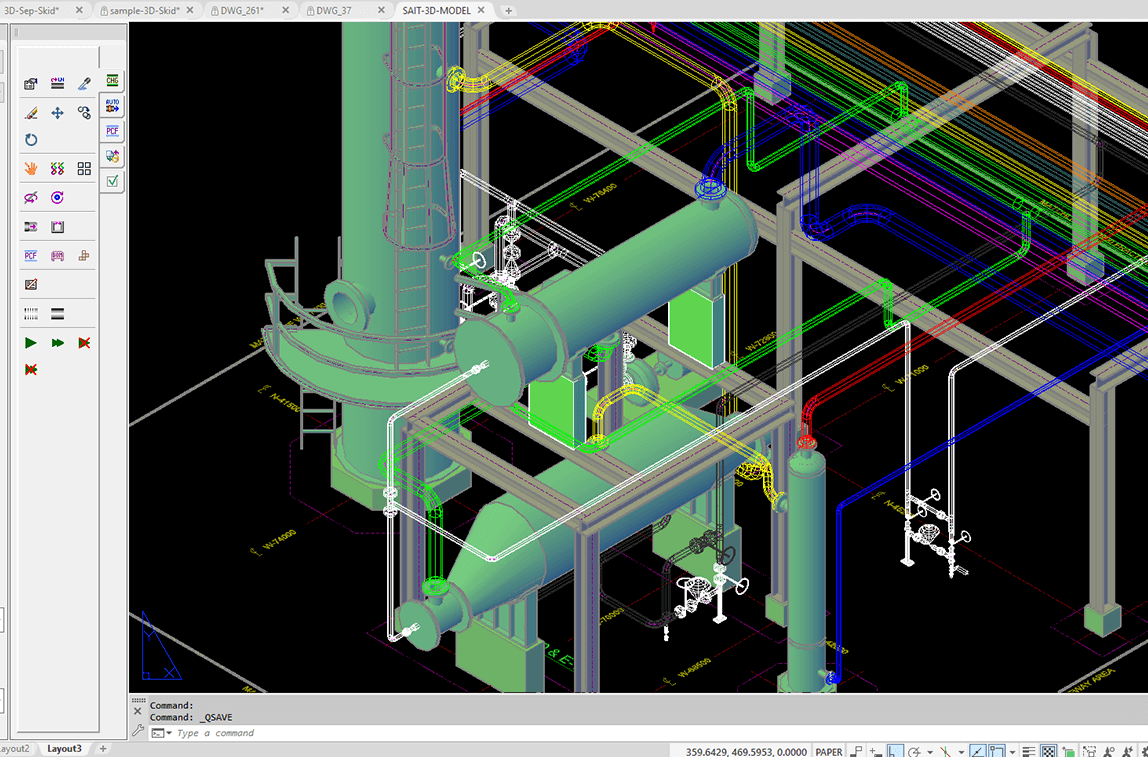

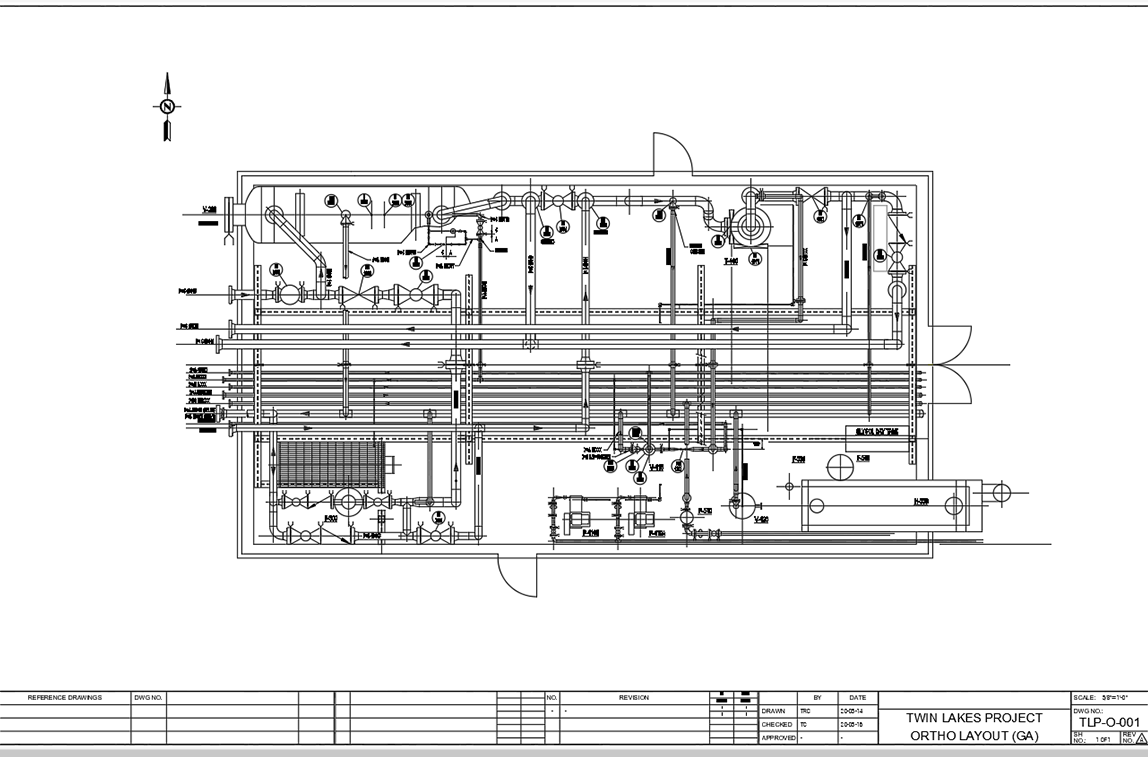

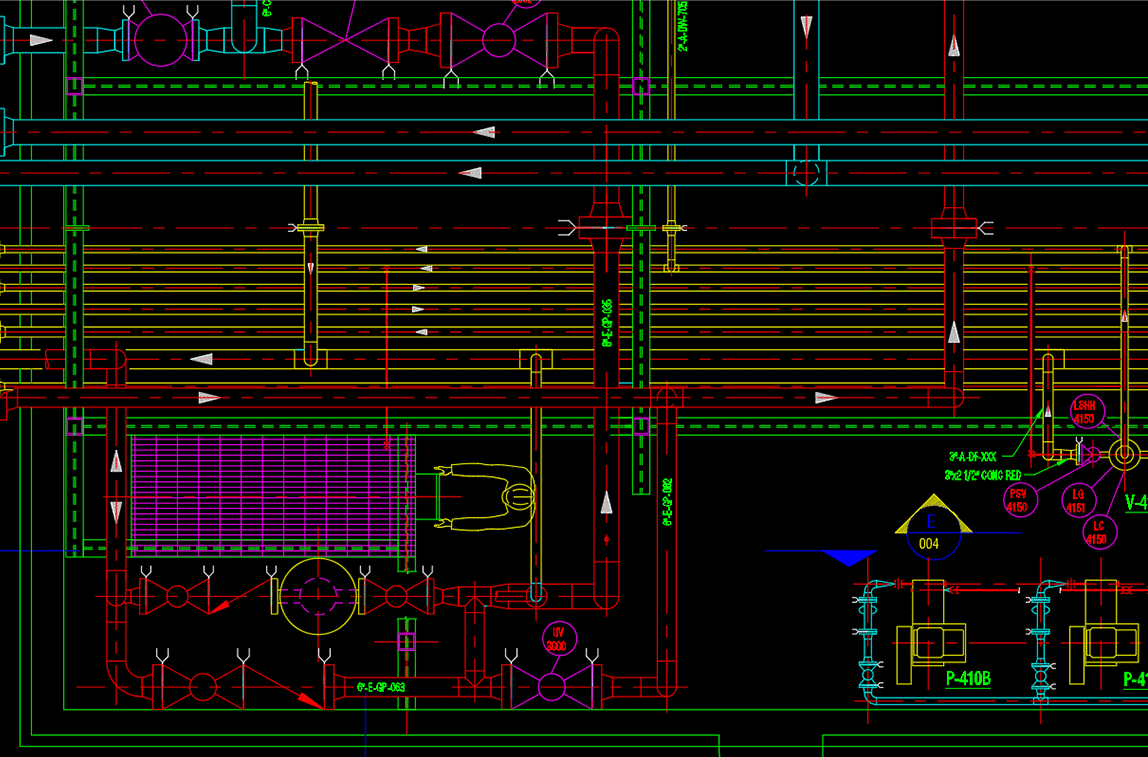

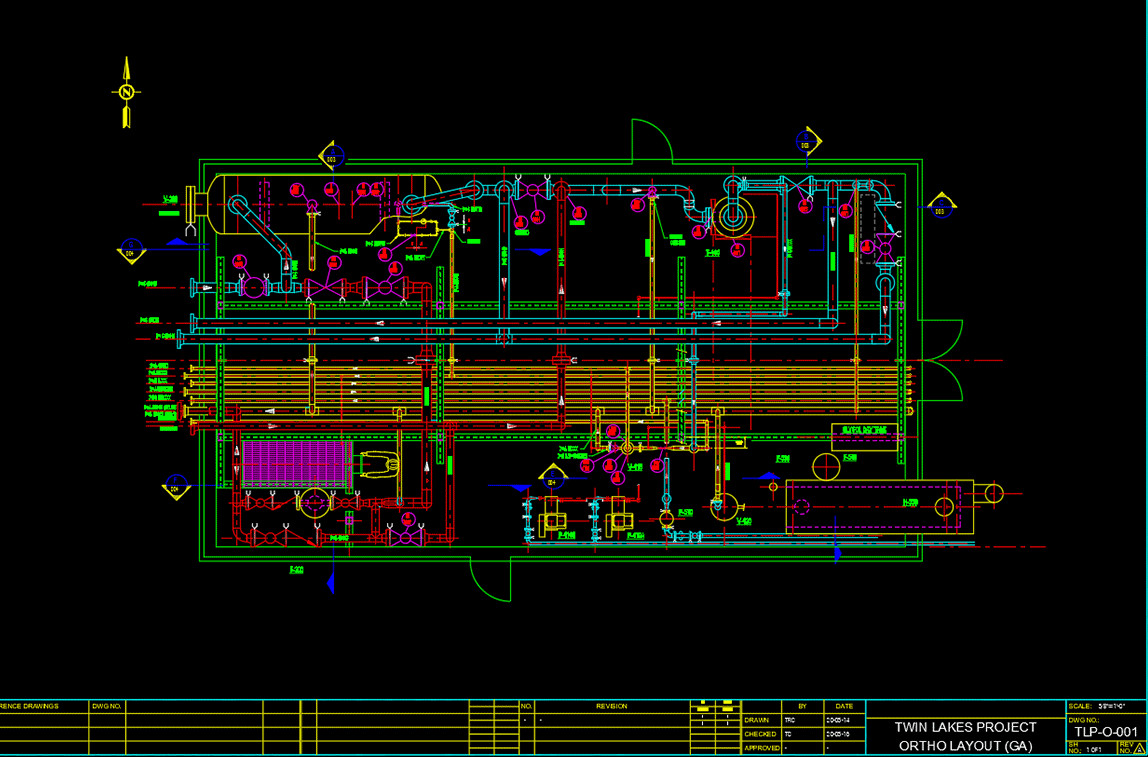

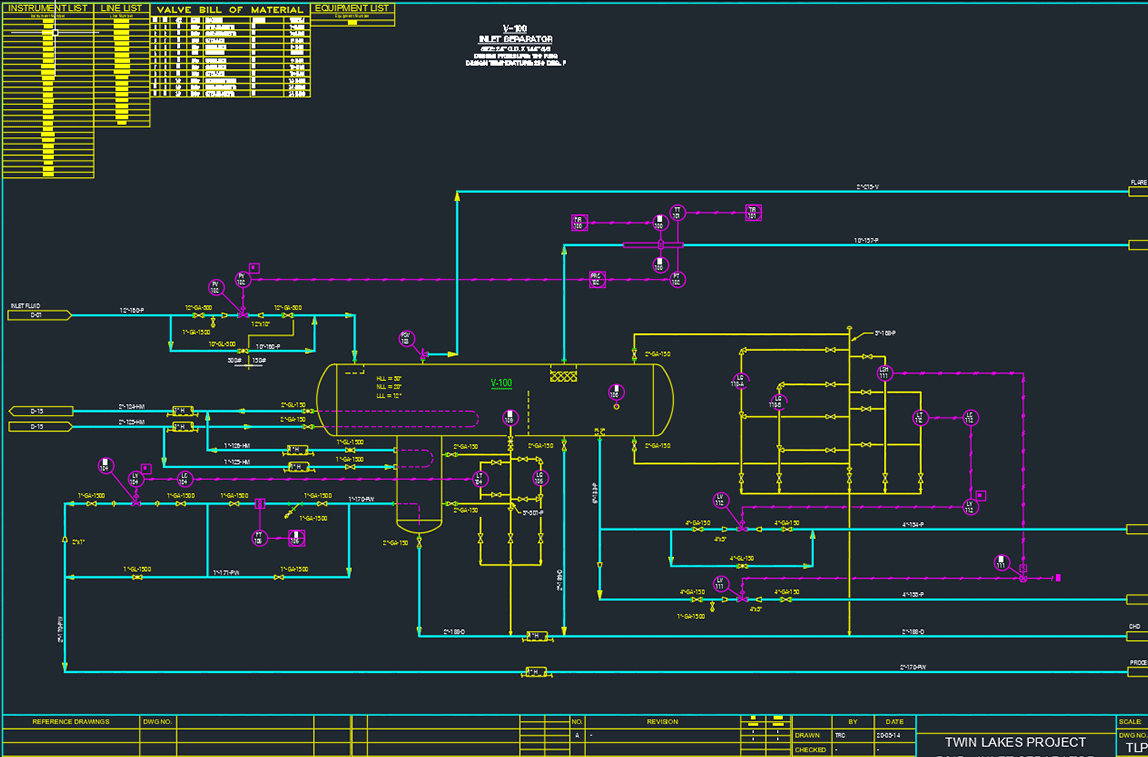

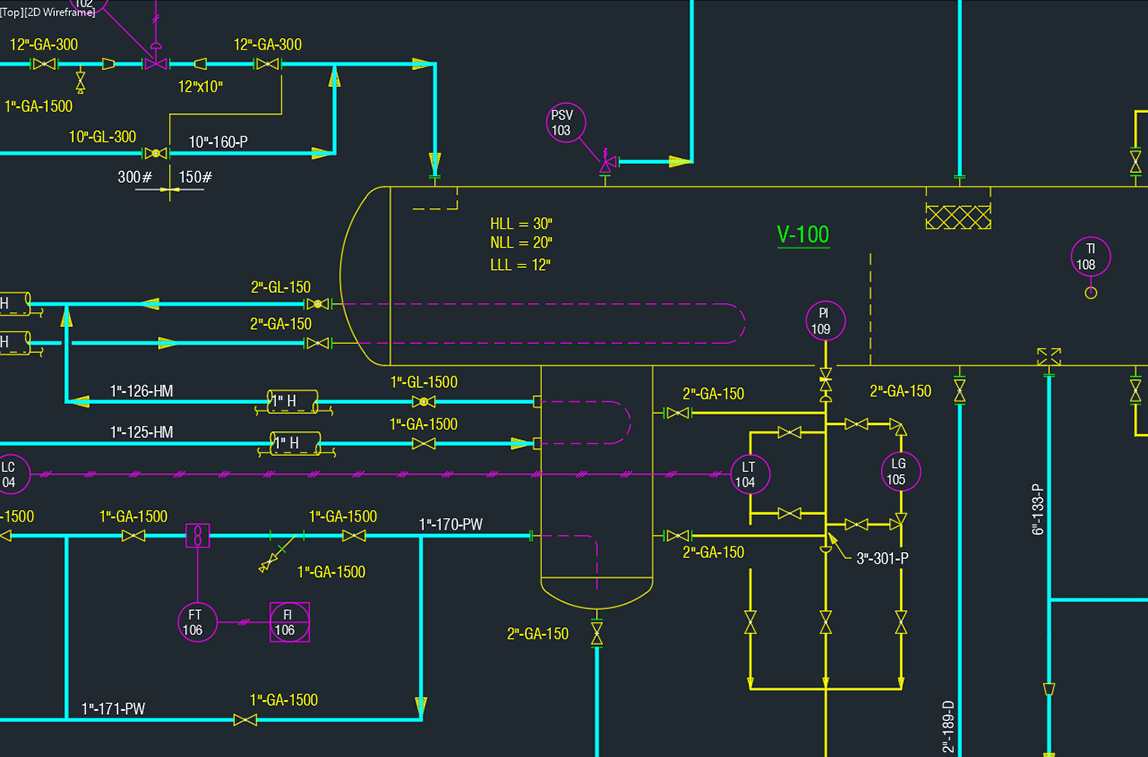

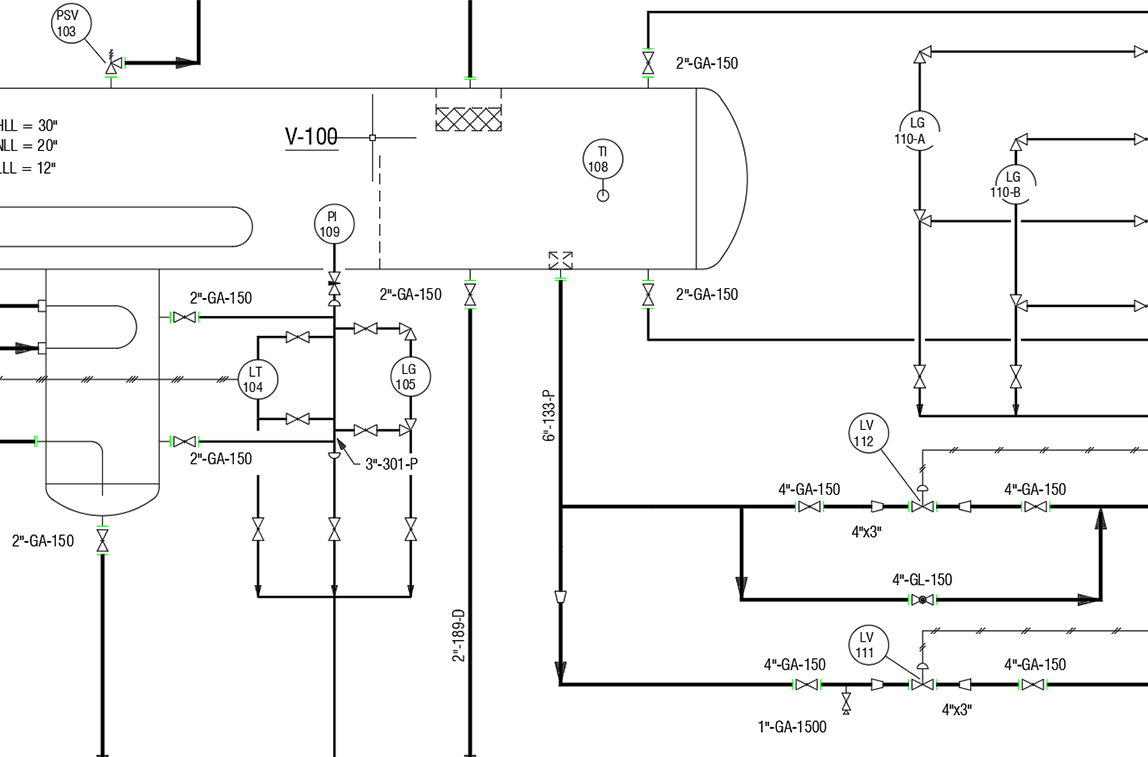

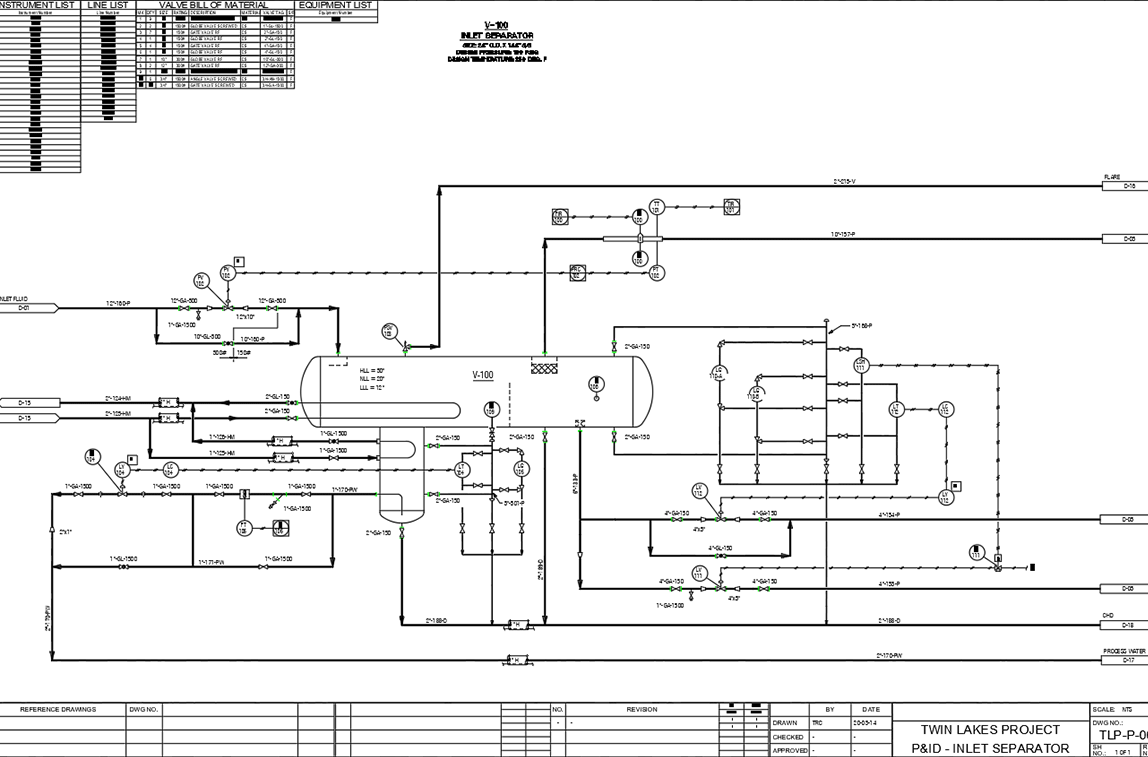

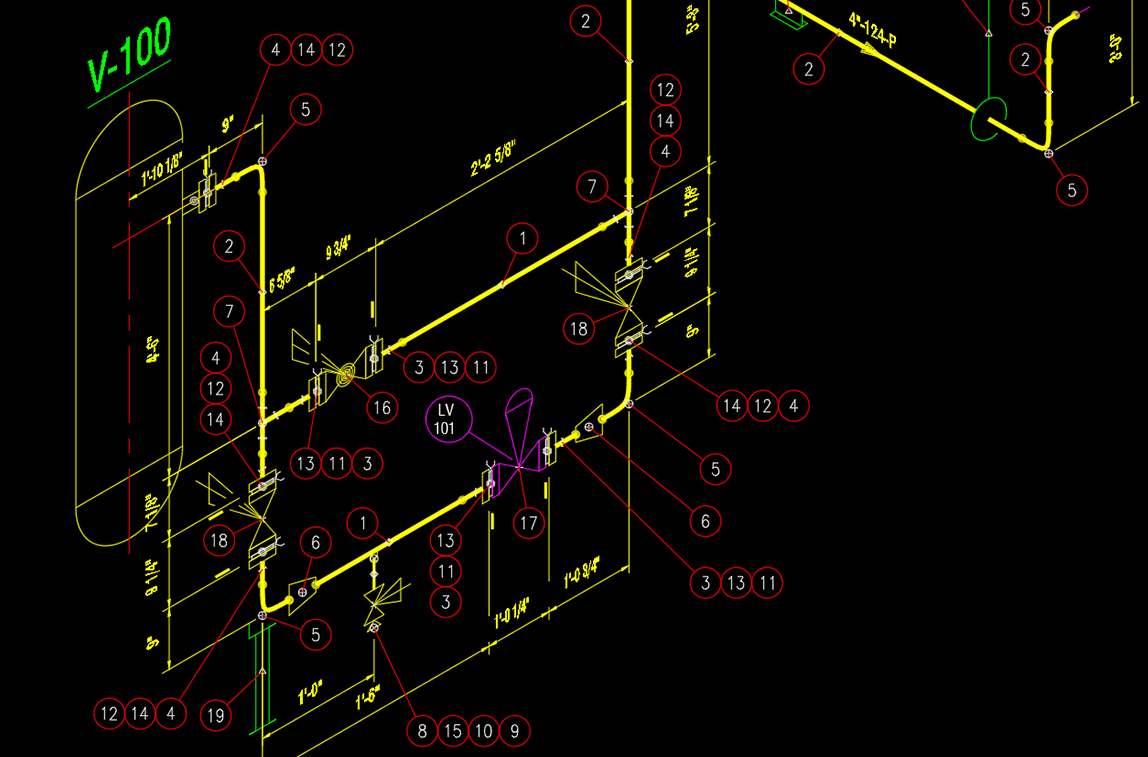

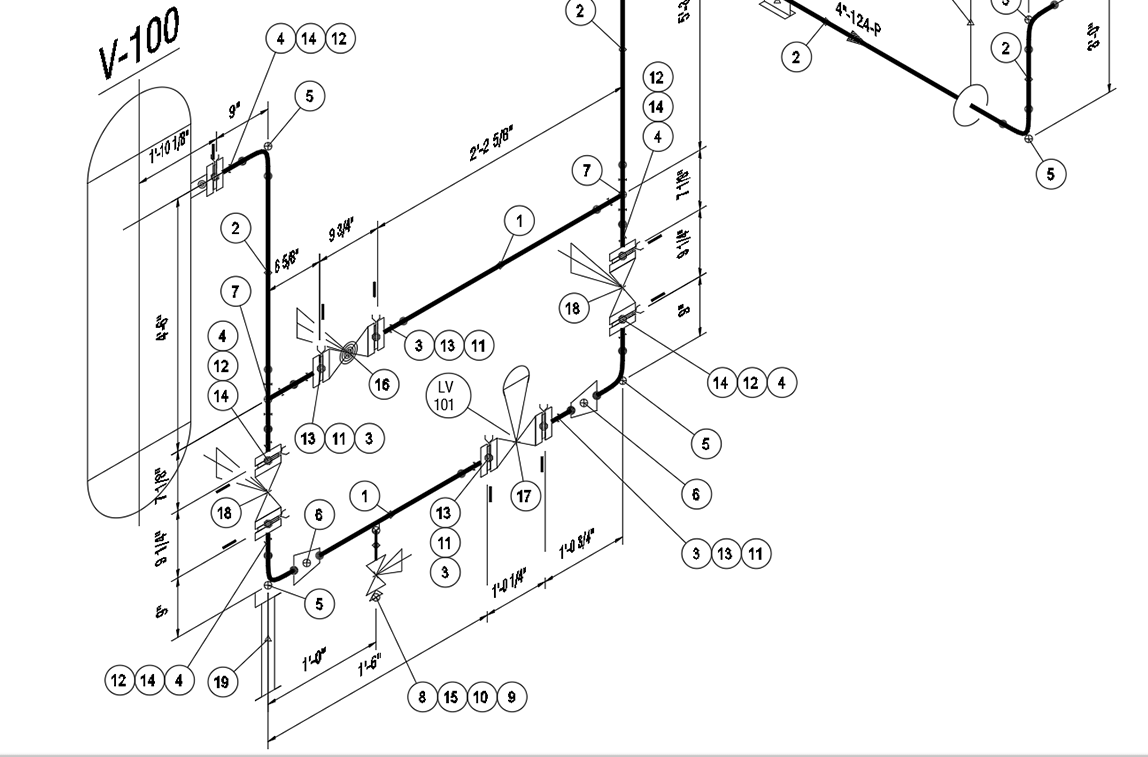

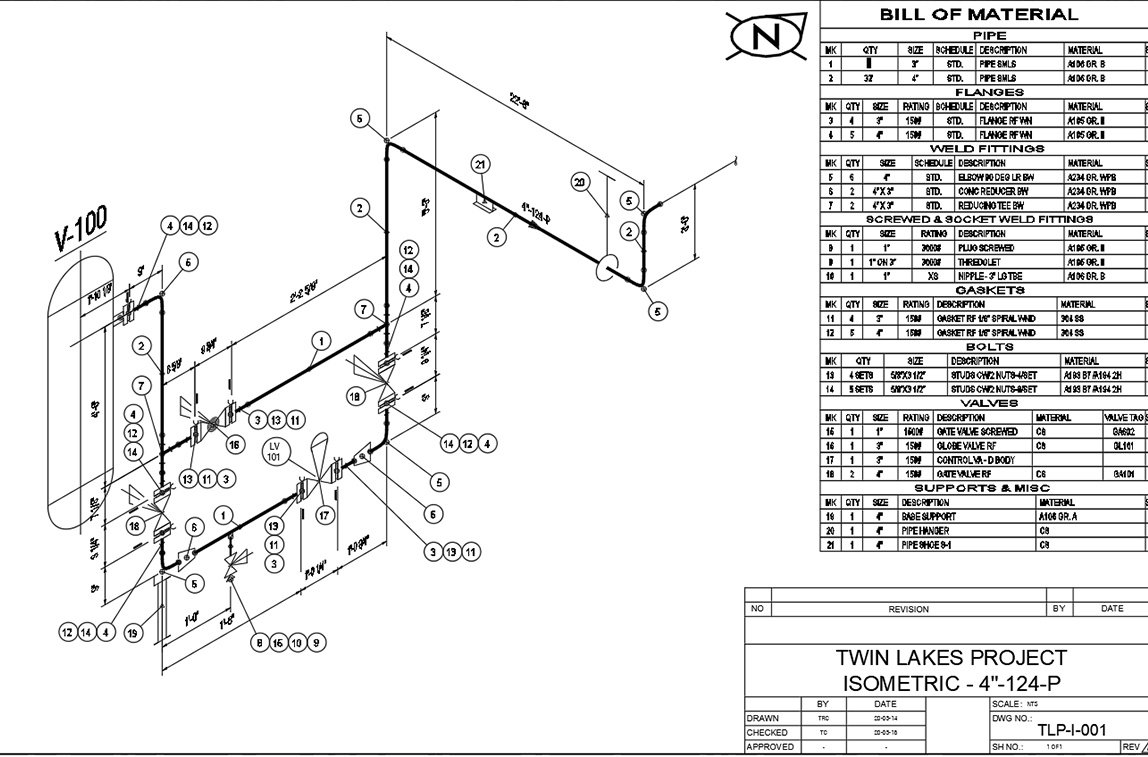

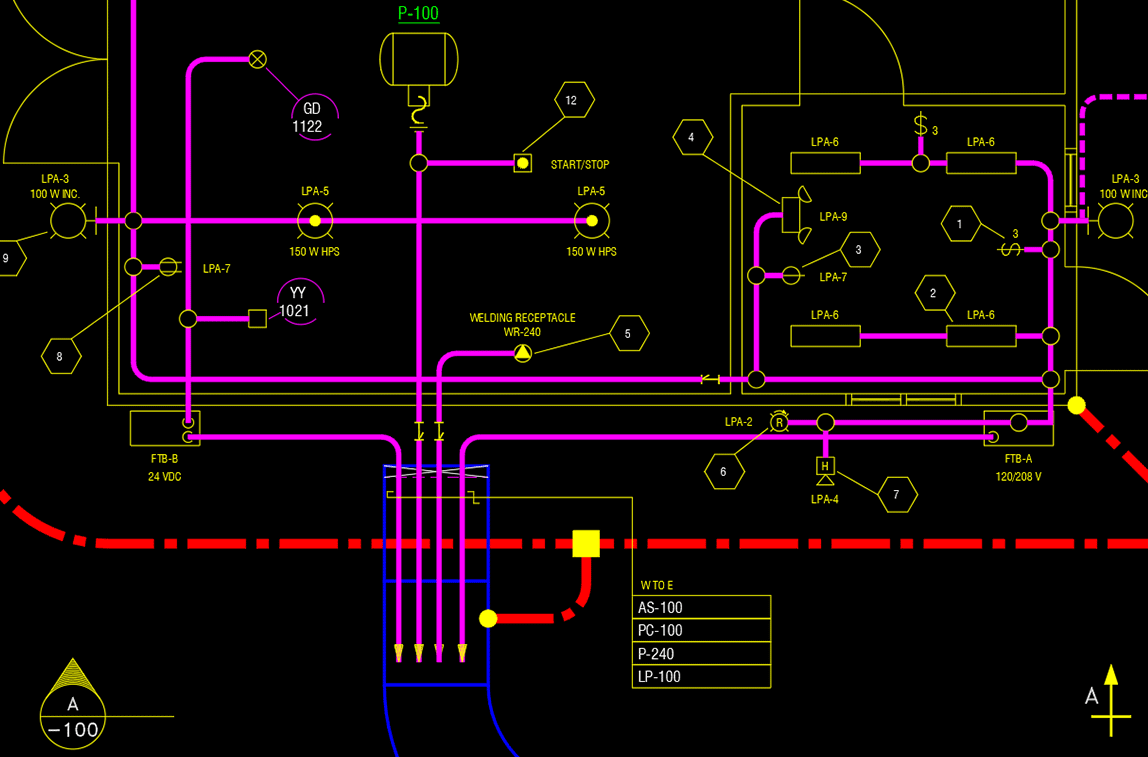

This does not only apply to equipment such as pumps or vessels, but even more critically to the piping systems. Interconnecting pipelines move the processed material throughout the plant. They are subjected to constant stresses from expansion, vibration and other factors, they have to be put together with a high standard of quality workmanship.

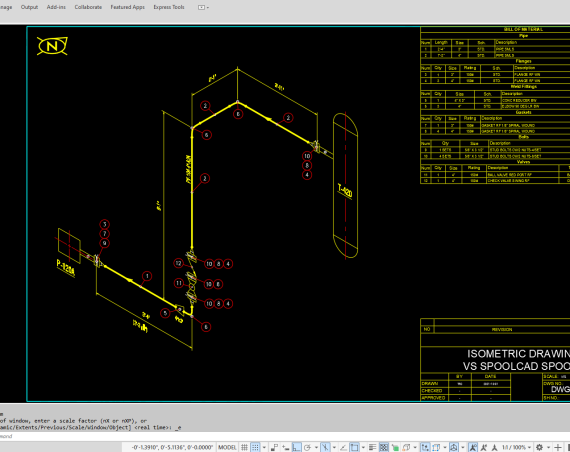

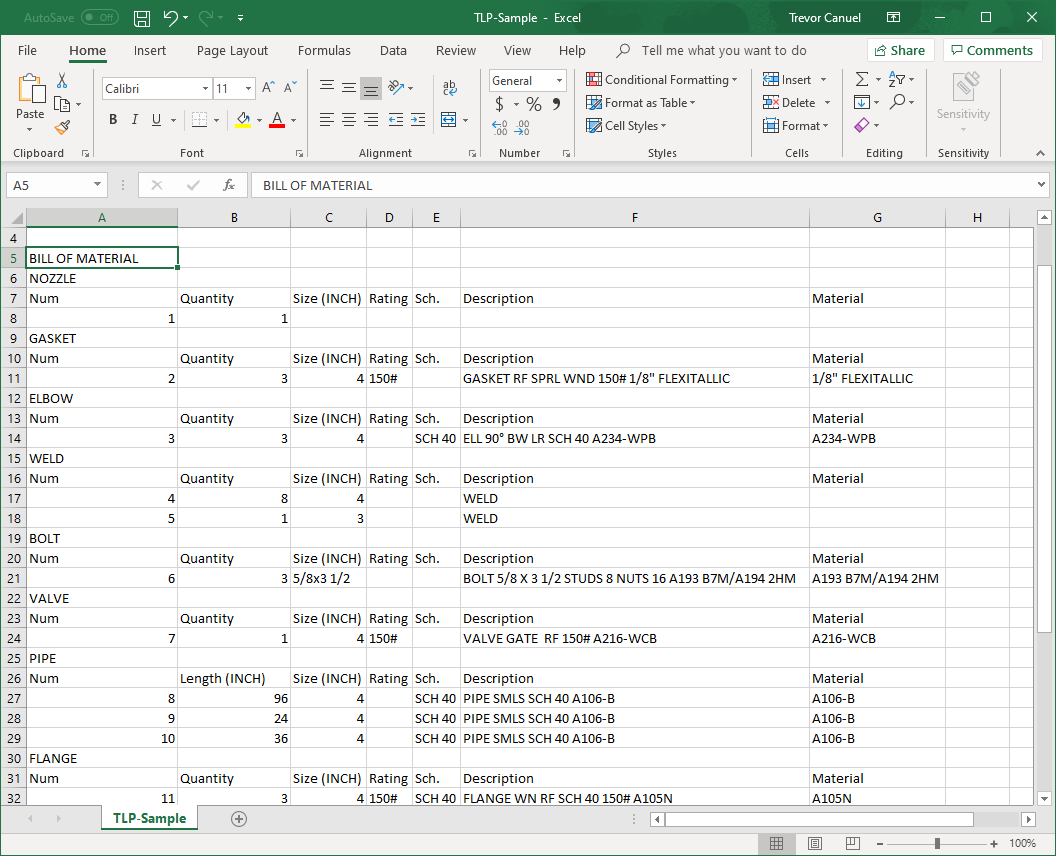

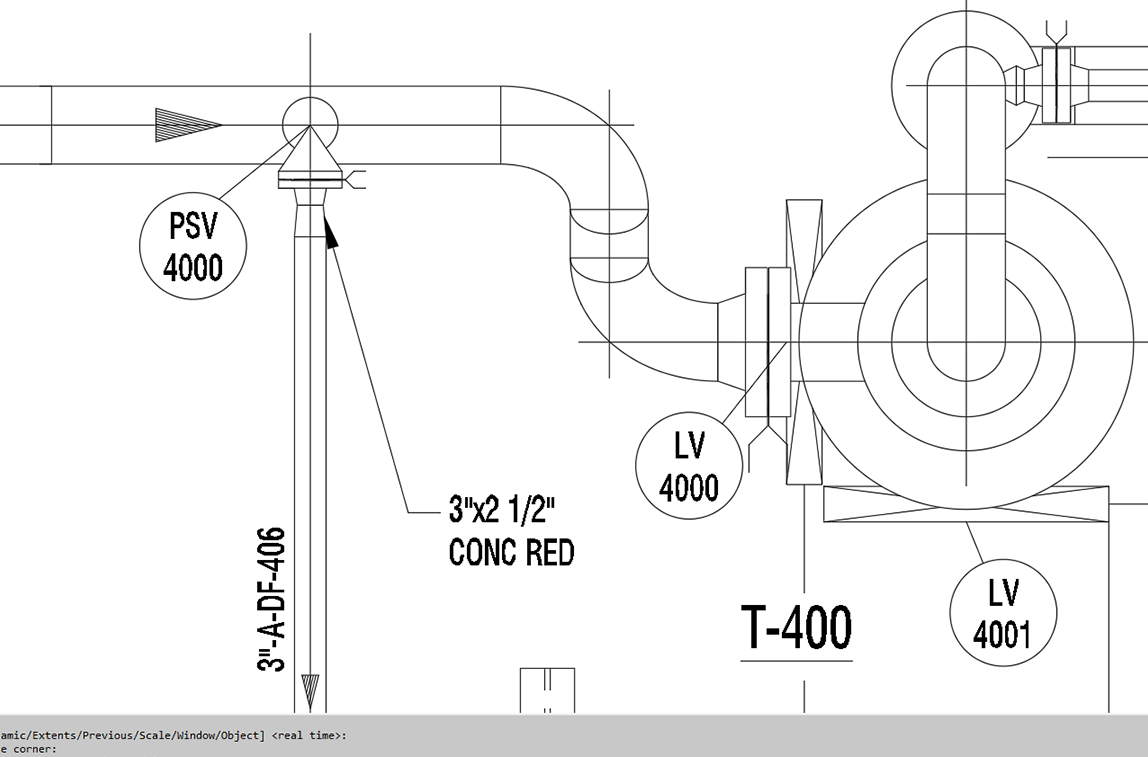

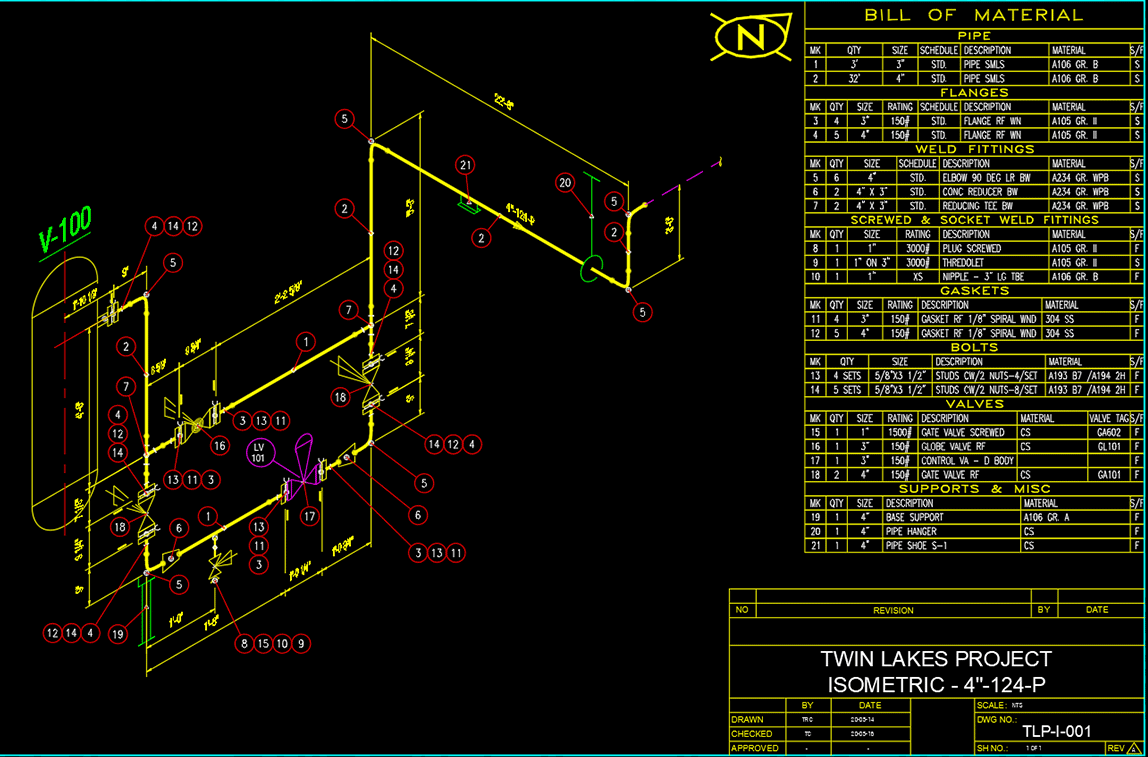

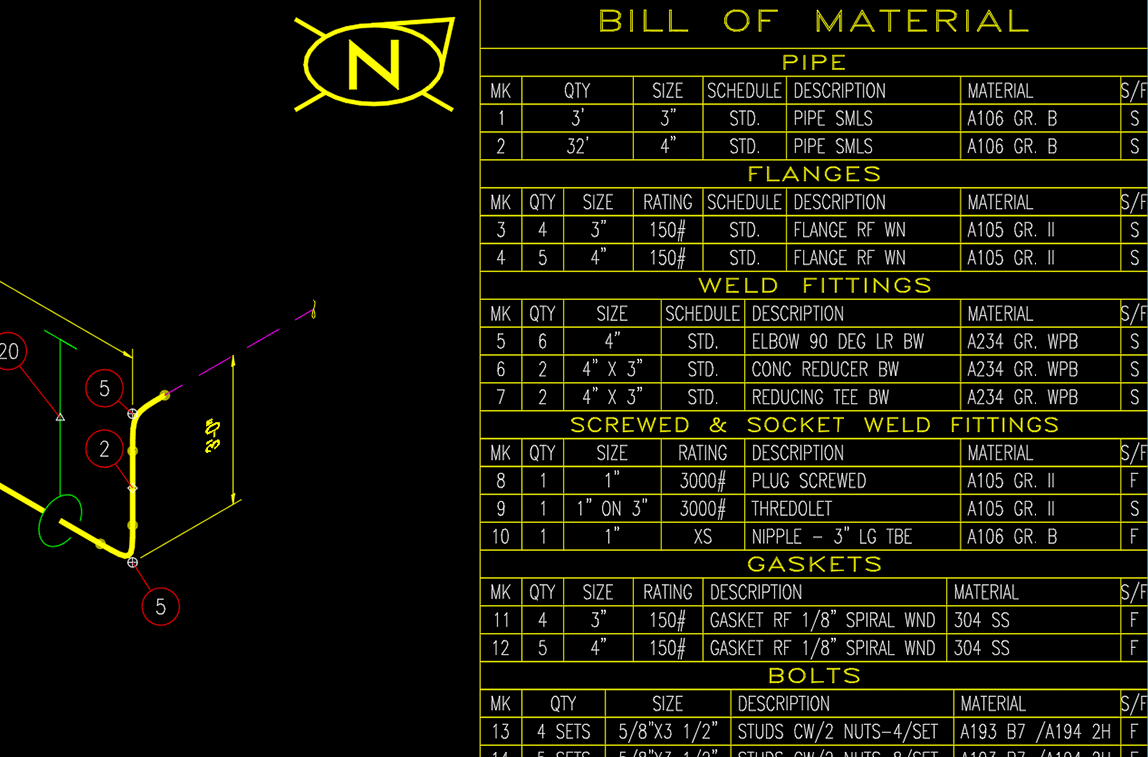

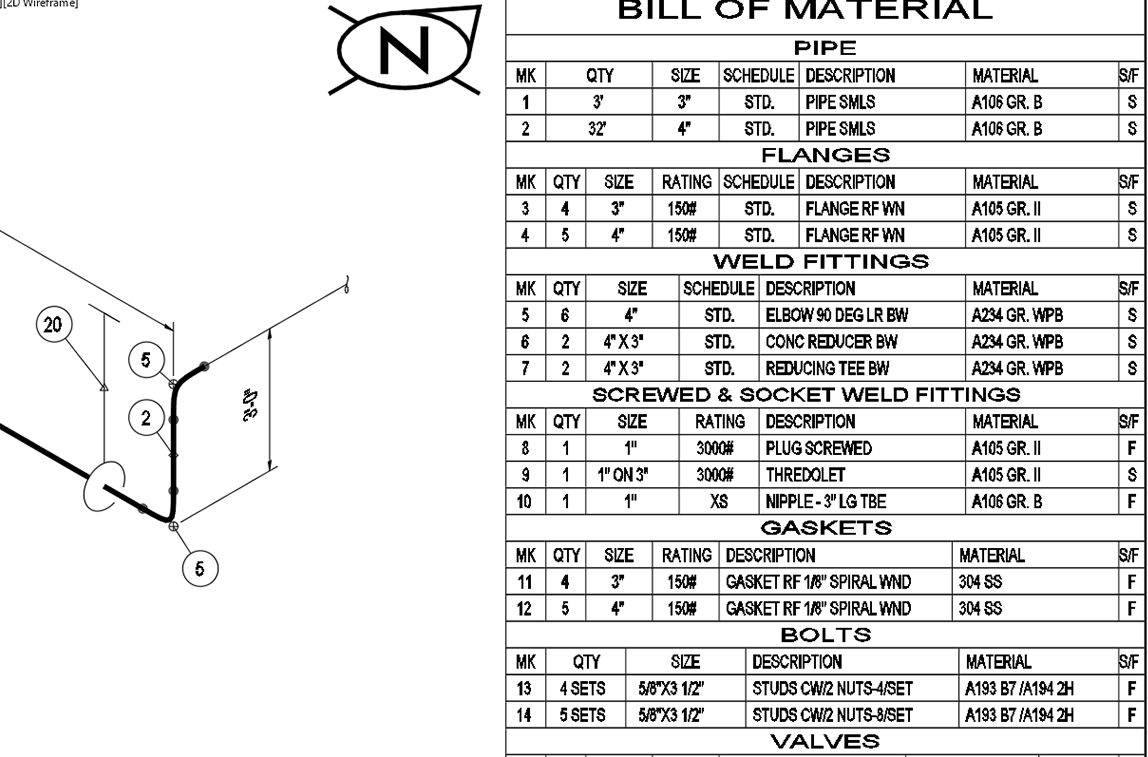

When fabrication shops build pipe spools, they rely on drawing information to keep good records of the welding the procedures used during construction. Welds are vulnerable to failure when not done correctly and that leads to serious problems with personnel safety, spills and unwanted shutdowns.

SpoolCAD was designed to help pipe fabrication shops keep track of welds by listing pertinent identifying data on the welder, x-ray procedures and other quality control procedures. It makes pipe fabrication more efficient with a higher level of quality control during the manufacture of spools that power these plants.